Diamond saw blade or diamond saw blade is one of the most widely used cutting tools in various industries. Reputable manufacturers in the world design and manufacture it, all of which follow the same standards, and the only differences in manufacturing engineering, such as the type of disc body coating, segment-to-body welding method, the type of noise distinguish them.

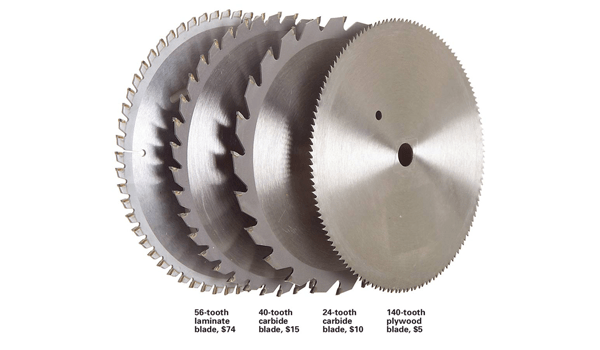

Each saw blade is designed and manufactured for a specific or batch of materials for cutting. It is advisable to pay enough attention to the diameter of the shaft according to the consuming machine, the number of teeth for the workpiece and the angle of the teeth for the type of cutting that will be done.

In the following, we will introduce the general features of different types of disc saw blades by mentioning the standard sizes and how to place their segment. Join Adox to become more powerful in your choice!

Wood saw blade

This blade is for cutting different types of soft, hard, wet and dry wood. Depending on the type of work in the direction of rapids (horizontal cut) and non-rapids (vertical cut) in various sizes, it creates quality cuts, without fading and burning and blackening of wood. The position of the segments is 15+ degrees and left and right (WS). This saw blade can be used for cutting machines, Persian saws and other woodworking machines.

| Diameter mm |

shaft mm |

Number of teeth | Diamond thickness mm |

Body thickness mm |

| 18 | 30 | 42 | 3/2 | 2/2 |

| 20 | 30 | 48 | 3/2 | 2/2 |

| 25 | 30 | 48-60 | 3/2 | 2/2 |

| 30 | 30 | 60-72 | 3/2 | 2/2 |

| 35 | 30 | 72-84 | 3/5 | 2/5 |

| 40 | 30 | 96 | 4/0 | 2/8 |